Sure, here’s the first part of the article, as per your request. Since you asked for it to be split into two parts, I’ll ensure this part addresses the initial aspects of optimization, and the second part will build on it.

Understanding the AR8035-AL1A and Its Role in Industrial Networks

In today’s rapidly evolving industrial landscape, Ethernet connectivity is essential to the functionality of industrial networks, enabling Communication between diverse devices, sensors, controllers, and other machines. With the increasing demand for faster, more reliable, and cost-effective solutions, the AR8035-AL1A Ethernet PHY (Physical Layer Transceiver) from Microchip Technology stands out as an ideal choice for industrial networks. But as industrial applications grow more complex, optimizing the performance of this critical component becomes vital to maintaining system efficiency.

What Is the AR8035-AL1A Ethernet PHY?

The AR8035-AL1A is a single-port, low- Power Ethernet PHY designed for high-speed networking in various industrial applications. As a physical layer device, it operates between the media access control (MAC) layer and the actual transmission medium—such as copper cables or fiber optics—providing the crucial interface between the digital signal processing components and the physical network infrastructure. In essence, the AR8035-AL1A converts digital data into electrical signals that can travel over the Ethernet cable and vice versa.

Unlike standard consumer-grade Ethernet PHYs, the AR8035-AL1A is specifically tailored for industrial environments, where reliability, energy efficiency, and durability are paramount. This Ethernet PHY is particularly suitable for applications in automation systems, industrial controls, remote monitoring systems, and other critical industrial sectors.

Key Features of AR8035-AL1A

Low Power Consumption: The AR8035-AL1A is designed with power efficiency in mind, which is crucial for industrial systems that often require 24/7 operation. Its advanced power-saving features allow for lower energy consumption while maintaining robust performance, making it ideal for applications in power-sensitive environments.

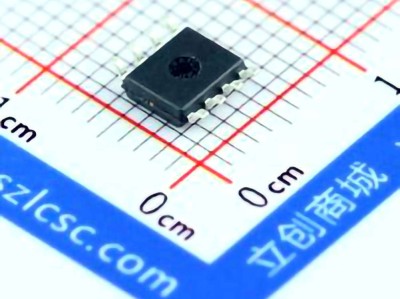

Small Form Factor: With its compact design, the AR8035-AL1A is ideal for industrial devices with limited space. This makes it a great choice for embedded systems and IoT devices that need reliable networking without compromising on space or efficiency.

Fast Data Rates: The AR8035-AL1A supports data rates of up to 10/100/1000 Mbps, allowing for flexible and scalable Ethernet communication. Whether a system needs basic connectivity or high-speed data transfer, the AR8035-AL1A can handle it.

Low Latency Communication: Industrial applications, particularly in automation and real-time monitoring, demand minimal latency for accurate control and communication. The AR8035-AL1A ensures efficient and low-latency data transmission, making it suitable for real-time applications.

Enhanced Signal Integrity: The AR8035-AL1A employs technologies to minimize signal distortion and interference, which is essential for reliable data transmission in environments with high electromagnetic noise—such as industrial settings.

Advanced Diagnostics: The PHY also includes diagnostic features that help identify potential network issues early on, allowing operators to address problems before they cause significant disruptions.

The Need for Optimization in Industrial Networks

While the AR8035-AL1A Ethernet PHY offers impressive capabilities, optimizing its performance is crucial to maximize the potential of an industrial Ethernet network. Industrial environments often face unique challenges that standard network components might not be designed to handle, such as:

Harsh Environmental Conditions: Industrial networks are often exposed to high levels of electromagnetic interference ( EMI ), temperature fluctuations, dust, and humidity. These factors can degrade signal quality, leading to packet loss, latency, and communication failures.

High Traffic Loads: Industrial networks handle vast amounts of data from sensors, controllers, and other devices. The AR8035-AL1A must be optimized to ensure that it can handle the increased data traffic without compromising performance.

Real-Time Processing: Many industrial applications, such as robotics, require low-latency, real-time communication for accurate control and coordination. Optimizing the AR8035-AL1A to handle these specific needs can ensure that these systems operate efficiently.

Effective optimization not only improves the overall performance of the AR8035-AL1A but also enhances the reliability and scalability of industrial networks, ensuring seamless operations and reducing downtime.

Power Efficiency Optimization

One of the most important aspects of industrial network optimization is power efficiency. The AR8035-AL1A is already designed with power-saving capabilities, but further optimization can provide significant benefits, especially in power-constrained environments.

In industrial networks, reducing power consumption is crucial for several reasons:

Cost Savings: Lower energy consumption translates directly into reduced operational costs, which is especially important in large-scale industrial operations.

Heat Management : Excessive power consumption generates more heat, which can affect the lifespan and reliability of network devices. By optimizing power use, industrial systems can run cooler and more efficiently.

Sustainability: As industries push for greener, more sustainable operations, optimizing power usage across all devices—especially core components like Ethernet PHYs—becomes a key part of an environmentally responsible strategy.

To optimize power consumption, industrial networks can leverage features like the AR8035-AL1A’s low-power modes, dynamic power adjustment, and reduced idle power consumption. Implementing intelligent power management strategies, such as adjusting power consumption based on network traffic, can help ensure that power usage is minimized without compromising network performance.

Signal Integrity and EMI Mitigation

Industrial environments are typically rife with electrical noise, which can severely impact the integrity of Ethernet signals. The AR8035-AL1A includes advanced features for mitigating electromagnetic interference (EMI) and improving signal integrity, but these features can be further optimized through proper PCB layout, grounding, and shielding.

A robust signal is key to maintaining reliable communication between devices in an industrial network. By focusing on minimizing signal degradation, packet loss, and ensuring high-quality data transmission, operators can prevent costly downtime and system failures. Some strategies for optimizing signal integrity include:

Optimized Trace Layout: Ensuring that Ethernet traces on the PCB are designed with optimal length, width, and spacing helps minimize signal reflections and crosstalk.

PCB Layer Stackup: Using the right stackup configuration with sufficient ground planes can help reduce noise and ensure a clean signal path.

Shielding and Grounding: Proper shielding of the Ethernet cable and PCB traces, along with effective grounding techniques, can prevent EMI from impacting the data transmission, ensuring clean and uninterrupted signals.

Low-Latency and Real-Time Communication

Low latency is critical for real-time industrial applications. The AR8035-AL1A offers features like jumbo frame support and low-latency transmission modes, but careful optimization can ensure even faster, more reliable communication.

By adjusting the PHY’s configuration to reduce latency and optimize packet processing, industrial networks can benefit from faster data delivery and improved response times. This is especially important in applications like robotics, factory automation, and remote monitoring systems, where real-time communication is essential.

Advanced Optimization Strategies for the AR8035-AL1A Ethernet PHY

In part 2, we will explore deeper into advanced optimization strategies for the AR8035-AL1A, covering more specific techniques for boosting performance, improving diagnostics, and ensuring system reliability.

Let me know if you need further adjustments or additional insights for Part 2!

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.