Understanding the AO3400 and Common Troubleshooting Scenarios

The AO3400 is a well-known and widely used component in many electronic devices, renowned for its performance, reliability, and efficiency. However, like any piece of technology, the AO3400 can experience operational issues due to a variety of factors such as wear and tear, improper usage, environmental conditions, or software bugs. In this first part of our troubleshooting guide, we will explore the common issues associated with the AO3400, how to diagnose them, and the best solutions to restore its functionality.

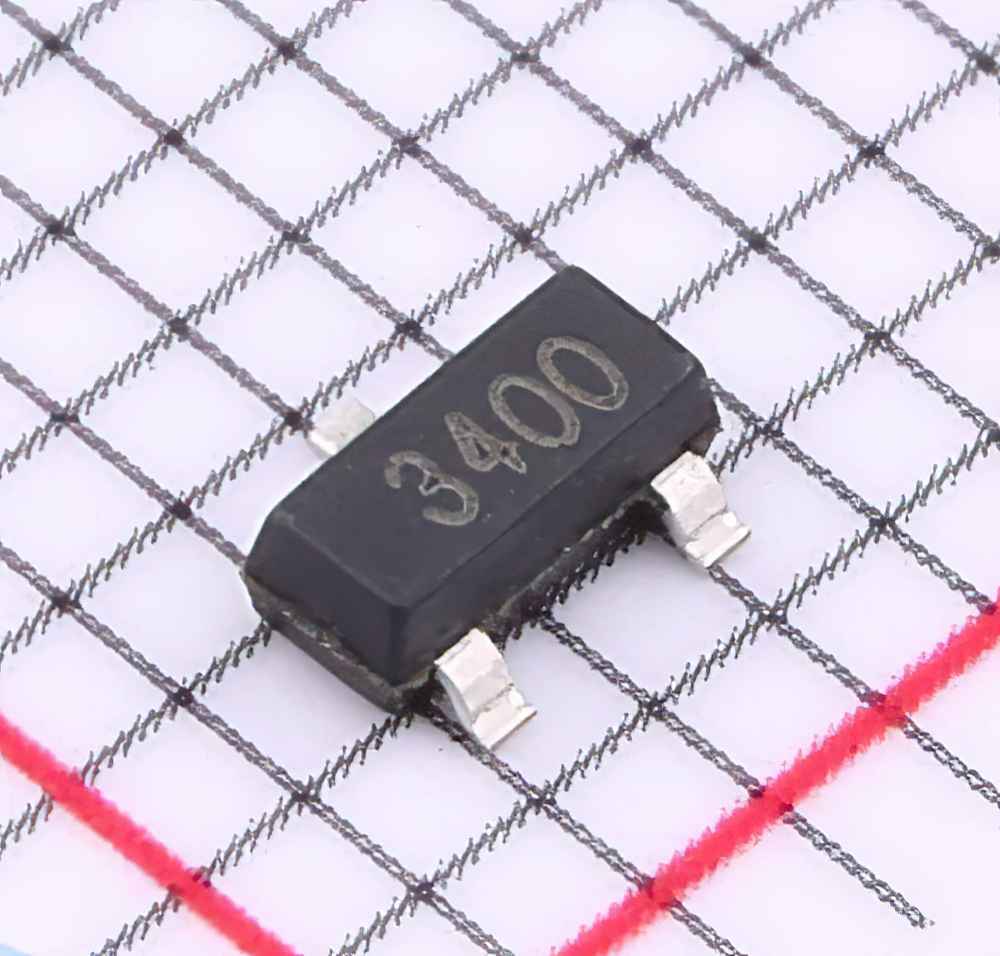

1. What is the AO3400?

Before delving into troubleshooting, it’s essential to understand what the AO3400 is and why it’s such a critical component in various systems. The AO3400 is typically a type of MOSFET (Metal Oxide S EMI conductor Field Effect Transistor), widely used in low-voltage circuits. It is valued for its efficiency, small size, and ability to handle high switching speeds. It is commonly found in consumer electronics, automotive electronics, and other devices where efficient Power management is key.

Despite its reliability, the AO3400 can face a few operational hiccups due to internal or external factors. Let’s take a closer look at the typical problems users might encounter.

2. Common Troubleshooting Issues with AO3400

Issue 1: AO3400 Not Powering On

One of the most common problems with the AO3400 is failure to power on, which can be frustrating. This problem may stem from several causes, including:

Faulty Connections: If the AO3400 isn’t connected properly within the circuit or if there’s a loose wire, it won’t be able to power the device as expected.

Overcurrent Protection: The AO3400 might go into an overcurrent protection state if too much current flows through it. This could cause the component to shut down to prevent damage.

Power Supply Problems: If the power supply feeding the AO3400 is unstable or not delivering the correct voltage, the component won’t function properly.

Solution:

Double-check the wiring and connections to ensure that everything is correctly attached.

Check the input voltage to ensure it matches the specifications for the AO3400.

If overcurrent protection is triggered, use a multimeter to measure current and voltage levels, adjusting them as needed.

Issue 2: Overheating and Performance Degradation

The AO3400 is designed to work efficiently at a particular temperature range. If it overheats, performance can degrade, or the component could even fail completely. Overheating issues often arise due to:

Insufficient Cooling: If the AO3400 is in an enclosed space without proper ventilation, it can quickly become too hot, especially under heavy loads.

Excessive Current: Using the AO3400 beyond its rated current capacity can generate excess heat, causing overheating.

PCB Layout Issues: Poor layout of the printed circuit board (PCB) can prevent the AO3400 from dissipating heat effectively.

Solution:

Ensure there’s adequate cooling or ventilation around the AO3400 to maintain optimal temperature levels.

Check that you’re operating the AO3400 within its specified current limits.

Inspect the PCB for heat-sensitive areas and redesign the layout if necessary to promote better heat dissipation.

Issue 3: Signal Noise and Interference

Another common problem with the AO3400 is signal noise, which can cause erratic behavior in circuits. This noise can arise from:

Electromagnetic Interference (EMI): The AO3400, like other sensitive electronic components, can pick up EMI from nearby devices or circuits.

Grounding Issues: Improper grounding or a ground loop can lead to noisy signals, affecting the AO3400’s performance.

High-Frequency Oscillations: In some cases, the AO3400 can generate high-frequency oscillations, which can interfere with other components.

Solution:

Add shielding around the AO3400 or employ EMI filters to reduce interference.

Inspect grounding and ensure proper grounding techniques are followed to eliminate ground loops.

Use decoupling Capacitors or other filtering components to smooth out high-frequency noise.

3. How to Diagnose AO3400 Problems

Diagnosing problems with the AO3400 is an essential first step toward fixing any issues. Here’s a step-by-step process to identify the root cause:

Visual Inspection:

Start by visually inspecting the AO3400 and surrounding components. Look for any physical damage such as burnt marks, discoloration, or cracks.

Ensure that there are no loose or damaged connections on the AO3400.

Check Input Voltage:

Use a multimeter to verify the input voltage at the AO3400’s pins. Ensure the voltage is within the component's specified range.

Measure Current Draw:

Using a clamp meter or a multimeter in current mode, measure the current draw of the AO3400. If the current exceeds the rated limit, the component may be in overcurrent protection mode.

Thermal Checks:

Use an infrared thermometer to check the temperature of the AO3400. If the temperature exceeds its operating limits, it may be overheating.

Signal and Waveform Analysis:

Use an oscilloscope to observe the signal waveforms at the input and output of the AO3400. Unstable or noisy signals could point to underlying issues.

Advanced Solutions for AO3400 Troubleshooting and Maintenance

In the second part of this guide, we’ll dive deeper into more advanced troubleshooting methods and maintenance practices to keep your AO3400 running smoothly. These solutions involve a mix of preventative measures and repair techniques to tackle more complex problems.

4. Advanced Solutions for AO3400 Issues

Solution 1: Upgrading Heat Dissipation Systems

If overheating persists even after ensuring proper ventilation, it might be necessary to upgrade the heat dissipation system. Here are a few advanced options:

Heat Sinks: Attach high-quality heat sinks to the AO3400. These are metal devices that dissipate heat efficiently. Ensure that the heat sink has a good contact area with the component’s surface.

Active Cooling: If passive cooling isn’t enough, consider adding fans or even liquid cooling to the system. This can significantly reduce temperatures and improve the AO3400’s longevity.

Thermal interface Materials: Use high-performance thermal interface materials (TIMs) between the AO3400 and any heat dissipation elements to improve heat transfer.

Solution 2: Improve Power Supply Stability

A common cause of instability in AO3400 circuits is a power supply that fluctuates or is not able to deliver consistent voltage. To remedy this:

Use Voltage Regulators : Employ dedicated voltage regulators to ensure that the AO3400 receives a constant and regulated voltage supply.

Install capacitor s: Capacitors can help smooth out voltage spikes or dips that may otherwise affect the performance of the AO3400. Adding electrolytic capacitors at the power supply input and output can help stabilize the voltage.

Use Power Conditioning Devices: In environments with a lot of electrical noise, consider using power conditioning devices like surge protectors and isolation transformers.

Solution 3: Replace Damaged AO3400 Components

In some cases, the AO3400 might simply be damaged beyond repair, especially if it’s been subjected to extreme conditions such as overvoltage, short circuits, or prolonged overheating. When this happens, it’s best to replace the component:

Source Authentic Replacements: Ensure that the replacement AO3400 component is from a reliable source and matches the original specifications.

Soldering and Component Handling: When replacing the AO3400, take extra care to handle the new component carefully. Use the proper soldering techniques and equipment to avoid damage during installation.

5. Best Practices for Preventative Maintenance

While troubleshooting and repairs are essential when problems arise, preventing issues before they occur is even better. Here are some best practices to ensure the longevity and reliability of your AO3400:

Routine Inspection: Regularly inspect the AO3400 and surrounding circuitry for signs of wear, such as loose connections or heat damage.

Stay Within Specifications: Always operate the AO3400 within its rated voltage and current limits to prevent overloading.

Environment Considerations: Ensure the AO3400 is placed in an environment that adheres to its temperature and humidity specifications.

Keep Circuit Clean: Dust and debris can interfere with the AO3400’s functionality, so make sure the circuit board is clean and free of contaminants.

6. When to Seek Professional Help

While many AO3400 issues can be resolved with the solutions outlined above, there may be situations where the problem is more complex, requiring Specialized knowledge or equipment. In these cases, it’s wise to seek professional help:

Specialized Equipment: If the issue involves deep circuit-level diagnostics, tools like an advanced oscilloscope or spectrum analyzer might be required.

Complex Circuit Failures: If the AO3400 is part of a larger, more complex system, pinpointing the exact cause of the failure may be beyond basic troubleshooting.

Conclusion

Troubleshooting and maintaining the AO3400 can be straightforward when you know what to look for and how to address common issues. By following the diagnostic steps and applying the solutions discussed in this guide, you can ensure that your AO3400 operates at peak performance for years to come. Regular maintenance, a proactive approach to repairs, and attention to detail will go a long way in preventing potential issues and extending the lifespan of your components.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.